Turn-key automation for the aerospace industry

ONExia Aerospace offers a variety of custom machines and tools designed for applications in the aerospace and composites industry.

Our engineers put the end-user first by making these tools and machines easy and ergonomically safe to use.

Aerospace & Composites Manufacturing

All of our solutions are designed and engineered in Exton, PA with the ability to be shipped internationally. For more information regarding doing business with ONExia, contact us today.

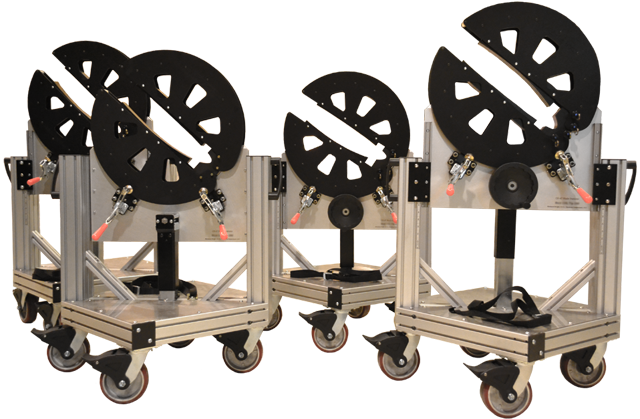

Rotor Blade Carts

No overhead tools, air, or power required.

The ONExia Blade Cart is a docking system that makes rotating and transporting blades safe and easy. Common logistical issues and operator fatigue are simultaneously eliminated.

By utilizing the blade’s center of gravity, the cart’s balanced, silicone-free design provides effortless rotation without the need for tools, air, or power.

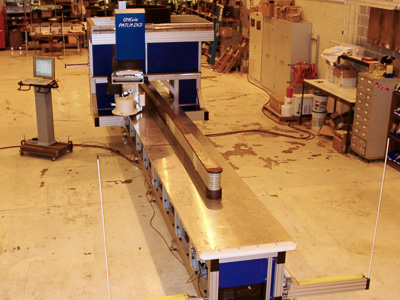

Universal Holding Fixture

A turn-key holding fixture that is completely sealed for water jet cutting during the composites manufacturing process.

This flexible tool approach adds to our customer’s bottome line through reduced tooling costs, reduced storage, quick changeover from part to part, higher throughput, and efficient space utilization.

Laser Templating Tower

Fast and simple to use tower for laser templating during manufacturing processes.

ONExia's Laser Light Towers make projecting a laser template fast and simple. Built to various heights the moveable tower makes it easy to display the image through a Virtek Laser other style OLT unit.

Our custom towers give the user the ability to move the projection system in ways that standard tripod systems cannot accomplish.

Turn-key automation

ONExia Aerospace has the knowledge and ability to provide you with a custom machine system designed to the specifics of your application. From hardware to software ONExia is your source for automation services.

Composite Tape Layup

- Layup of epoxy impregnated carbon fiber tape

- Layup around mandrel and slit cut for final use

- Programmable Layers and Slit Positions

Vacuum Tables

- Layup on a Table Surface

- Lid Lowers at Push of a Button

- Heat Applied from Top, Bottom, or Both

Composite Die Forming

- Unlimited Lengths Available

- Multiple Die Capacity with Automatic Activation

- Backing Tape Wound During Process

Drawbenches

- Capable of 2,000 lbs of Pull Force

- Programmable Pull and Return Speeds

- Speed Potentiometer Mounted to Electrical Panel for Changing Pull Speed

Custom Machine Systems

- Machines Designed to Meet Your Application Needs

- Machining in Various Parts

- Custom Weldment

- Custom CNC Software

Heat Mold Flipping

- Handle Male & Female

- Mold Halves

- Assemble Molds Without Cranes at the Push of a Button