Parker Rotary & Linear Motors

Parker offers a complete line of rotary and linear motors that can work Parker and other industry leading controllers. All motors come in a variety of sizes and also have IP rated options.

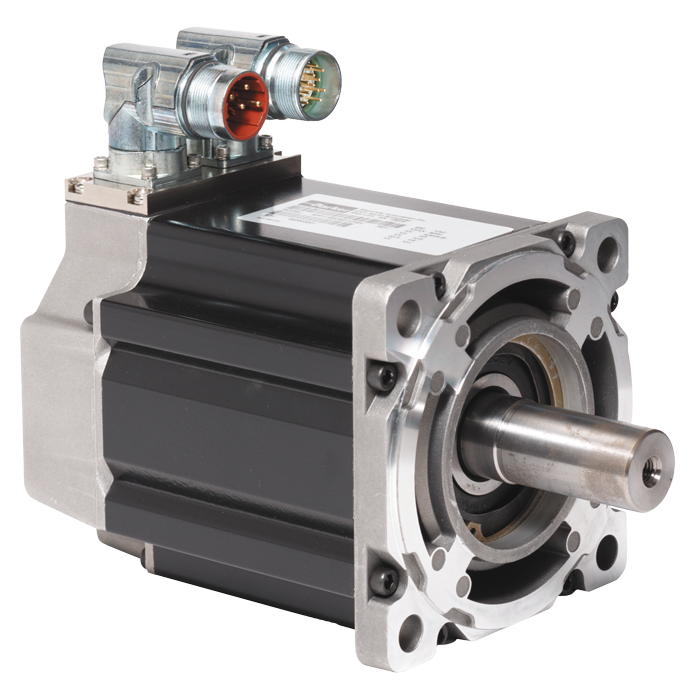

MPP/MPJ Series Motors

The MPP/MPJ Series features a new design that offers lower inertia and higher power, all in a smaller motor package. These brushless servo motors are designed for the demanding applications found in today’s high-performance servo systems.

The MPP motors feature segmented core technology, which can yield up to 40% higher torque per unit size than conventionally wound servo motors. “Potted” stators improve heat transfer for better thermal efficiency, resulting in increased torque at the motor shaft. High-energy neodymium magnets are employed for higher rates of acceleration.

- Sizes 92, 100, 115, 142, 190 and 270mm

- 12 to 1295 in-lbs continuous torque

- High torque density packaging

- Brushless Construction

- High performance Neodymium magnets

- Thermistor Protection

- 2000 line incremental, Resolver, Single/Multi-turn Absolute (EnDat and Hyperface).

- Right Angle “Rotateable” connections

- 3 – 21 day delivery

- Full Customizations available

- CE / UL Compliant

E Series Closed Loop Stepper System

The new eCL series introduces simple and precise closed loop control to Parkers microstepping product platform. The eCL system maintains the inherent advantages of stepper control while eliminating common disadvantages through the addition of an innovative closed loop control algorithm for optimum performance.

- Available in two driver form factors (4A) and (2A)

- 24VDC input

- Small, precise, high torque stepper motors with connectors

- EtherCAT and Step/Direction drive options

- All motors include encoders (Nema8, 11, 17, 23)

- Selectable resolution up to 50,000 steps/rev.

- Closed loop performance without tuning

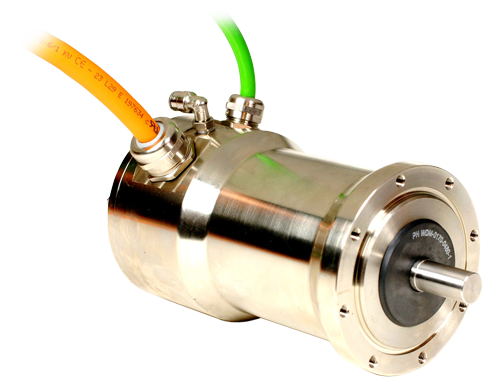

MPW Stainless Steel Servo Motor

The new MPW Series extends the MPP motor family to meet the needs of those applications exposed to high pressure, highly caustic, washdown environments. Specific applications can be found in such markets as Food and Beverage, Pharmaceutical, Packaging, and any other application that may be exposed to a harsh environment (salt, fog and humidity).

- 10 models covering three frame sizes

- Sealed to IP69K for 1200 psi washdown requirements

- Potted stator design for improved thermal efficiency

- 35 to 227 in-lbs continuous torque (230 and 460VAC supply)

- Options include high resolution encoders, resolvers, and 24 V brake

- Cable options available to plug and play with competitor drives

P Series Motors

The P Series brushless servo motors are the perfect match with P Series drives, providing high torque and fast settling times with one-touch tuning.

All motors include high resolution BiSS-C absolute encoders that populate motor nameplate data back to the drives for simplified commissioning. Economical, low profile cable connections help machine builders meet demanding size and budget requirements.

- 40, 60, 80 mm frame sizes

- 0.2 to 3 Nm (2 to 28 in-lb) continuous stall torque

- 0.5 to 10 Nm (4 to 85 in-lb) peak torque

- Allowable load inertia up to 30 x rotor

- BiSS-C absolute feedback, up to 524288ppr

- Performance matched

- 3000 rpm rated, 5000 rpm max speed

- Low-profile cable connections

SM Series Servo Motors

- Size 16 and 23

- 0.8 to 11.3 lb-in continuous torque

- Brushless construction

- Slotless design

- High performance neodymim magnets

- Thermostat protected

- TENV housing

- IP65 option

- Feedback options

- Connectorization choices

- Special winding availability

- Ten day deliveries

- Two-year warranty

- CAD (.dxf) drawings available

- CE Compliant

BE Series Motors

- Sizes 16, 23 and 34

- 1.4 to 46 lb-in continuous torque

- Brushless construction

- High torque density packaging

- Bridged stator design - quiet operation

- High performance neodymium magnets

- Thermoswitch protection

- 2000 line encoder standard

- Resolver feedback option

- Connectorization choices

- 10-day deliveries

- Two year warranty

- CAD (.dxf) drawings available

- CE Compliant

LV/HV Stepper Motors

- High performance

- Cost effective

- Optimized motors for both low-voltage and highvoltage applications

- Static torques from 6.5 to 1285 in-oz)

- LV: 11, 14, 17, 23, and 34 frame sizes HV: 17, 23, and 34 frame sizes

- Single, double, or triple stack lengths available

- LV: up to 80 VDC windings HV: up to 170 VDC windings

- Single or double shaft options

- Flying leads or 10-foot cable options

- Customization available

- Encoder options available

- CE (LVD)

Frameless Kit Motors

Frameless Kit Motors are the ideal solution for machine designs that require high performance in small spaces. Kit Motors allow for direct integration with a mechanical transmission device, eliminating parts that add size and complexity. Use of Frameless Kit Motors results in a smaller, more reliable motor package.

I-Force Ironless Linear Actuator

Parker I-Force ironless motors offer high force and rapid accelerations in a compact package. Parker’s patented I-beam shape, with its overlapping windings, allows for a higher power density in a smaller motor, improved heat removal, and added structural stiffness. A forgiving air gap and no attractive forces allow for easy installation and zero cogging during motion.

- 5 different cross sections (110, 210, 310, 410, and ML50) with up to 8 poles

- Compact size with high force density and superior heat removal

- Air and water cooling

- Vacuum rated to 10-6 torr

- Ultra high-flex cable standard

RIPPED Ironcore Linear Motors

Parker RIPPED ironcore linear motors, with their patented anticog technology, can produce the large forces needed for many industrial applications – without the roughness associated with traditional ironcore linear motors. The RIPPED family is well suited for a broad range of extremely demanding applications.

- Patented anti-cog technology for extremely smooth motion

- 3 different cross sections

- Single magnet row for high performance at an economical price

- Connector module allows for quick installation and easy cable management

- Ultra high-flex cable standard